Interview: Jerry Tate, Possibly the Oldest Watchmaking School Graduate Ever

I first got to know Jerry Tate through watch events we hosted at Christie’s while I served as Vice President, Senior Specialist of Watches there. It was a pleasure to see him follow his passion and dreams to leave his career as an engineer to attend watchmaking school at Oklahoma State University and then become a professional watchmaker in New York City. Since this interview was conducted, the Oklahoma State University Institute of Technology announced the closing of their Watchmaking and Microtechnology Program at the end of 2018 and Jerry was part of their last class. To the best of our knowledge, Jerry is the oldest formal watchmaking school graduate ever at the age of 62. Jerry is now 64.

I conducted this interview back in 2018 and happy to now have had the time to publish it in 2020 during The Great Quarantine. Watchmaking is such an important part of our hobby and my profession as a watch dealer and expert. I hope to continue to publish more of these in-depth interviews with interesting people in the world of vintage watches if watch enthusiasts enjoy them.

Eric: Tell me again, we’ve talked about this before; you previously worked as an engineer. What companies did you work for?

Jerry: Most of my career was with Honeywell Aerospace in Phoenix.

Eric: Where and what did you study?

Jerry: I went to Arizona State University where I studied Mechanical Engineering, I have a BSME.

Eric: And you left the aerospace industry in 2016?

Jerry: I developed missile and spacecraft attitude control systems at Honeywell from 1978 to 2001, when I moved to New York to be with my girlfriend, who is now my wife. I was a program manager at a couple of aerospace firms here in New Jersey and New York in the early 2000s.

Eric: And when did you become interested in watches and watchmaking?

Jerry: 2004

Eric: How did you get interested?

Jerry: The thing that opened my eyes was a magazine supplement in the New York Times.

Eric: Wow, and had you owned mechanical watches in the past?

Jerry: Well, now that’s the interesting part. At the time that I discovered watches I had a Seiko Lassale dress watch that was a college graduation gift and a Movado Museum watch, which were both quartz. As I got more interested in watches, I remembered I still had my high school Timex watch that had been in my dresser for 30 years. I pulled it out and I’m looking at this inexpensive Timex, and I just start turning the crown fiddling with it and it started running.

Eric: Wow.

Jerry: My hair stood up, I got goose bumps all over, because I realized that my first watch back in high school, that I bought brand new for $15 was a mechanical Timex. (laughs) That blew my mind, and instantly made me feel very old.

(both laugh)

Eric: That’s great.

Jerry: I quickly realized I bought that back at the beginning of the quartz watch revolution

Eric: Yeah, that’s amazing.

Jerry: I still have it, it still runs.

Eric: You still have it today?

Jerry: Yeah. I was in high school in Arizona and got interested in turquoise and silver jewelry, so I bought this very nice sterling silver watch bracelet with inlaid turquoise.

Eric: That’s awesome.

Jerry: I wanted an inexpensive silver looking watch to put on it, and it turns out that I bought a mechanical Timex with my paper route money.

Eric: Nothing fancy, just something cool! The next question is what lead you to watchmaking school?

Jerry: After graduating high school, I worked in a machine shop for four years while I was attending night school, trying to decide on a major. We made high-precision metal cutting tools: taps, reamers and thread gages, including miniature taps. When I discovered mechanical watches in 2004, I immediately felt that my machinist experience and aerospace engineering background made me highly qualified to be a watchmaker.

I looked into watchmaking schools, because at the time that I discovered watches I had recently lost my program manager position. My wife and I decided we needed a parent at home, so I became a full time stepdad to my wife’s two young boys. Since many watchmaking schools were tuition-free, I assumed I was too old to be a good watchmaking school candidate. I also didn’t have the opportunity to pursue it, since I was needed at home. So it was always a dream, but I never knew if there would ever be an opportunity.

Eric: Right, so then, you sort of began once your step son Will was off to college?

Jerry: Yes, it was late 2015 when I met you. Realizing my wife and I would soon be empty nesters, I became a National Association of Watch and Clock Collectors (NAWCC) and Horological Society of NY (HSNY) member. I went to a few different NYC auction exhibitions and coincidently met Nick Manousos, who is now the president of HSNY. I explained my background and interest in the watch industry and he suggested that I did have the opportunity to become a watchmaker. That was the first indication that there might be a possibility.

Eric: That’s great. Talk me through your process of looking at different schools.

Jerry: I first applied to the Lititz Watch Technicum and the North American Institute of Swiss Watchmaking (NAIOSW) in Dallas. I was not accepted by either school, unfortunately, despite my mechanical engineering background and career. One of those schools told me that I was too old for their program. After that, although I was slightly disheartened, I began researching the Oklahoma State University program.

Eric: I am sorry about the age discrimination! Just terrible. Tell me about the Oklahoma State University program.

Jerry: I applied to the Oklahoma State University Institute of Technology (OSUIT) program and visited the school to take their bench test.

Eric: And that was in Oklahoma?

Jerry: Yes, in Okmulgee, Oklahoma, about 40 miles south of Tulsa.

Eric: Tell me a little about the town.

Jerry: The population is about 12,000. The peak of population and activity in the town was about 1900 to 1930, with the oil industry being the major employer. The Oklahoma State University Institute of Technology is a significant presence in Okmulgee, with nursing, automotive, construction, energy technologies, manufacturing technologies, information technologies, culinary, visual communications and engineering technologies.

Eric: And tell me, then you were accepted and you began in January 2017?

Jerry: Correct.

Eric: And how many students are in your cohort?

Jerry: We started with 8 students, but one classmate left for health reasons, so we have 7 students.

Eric: And it’s a two-year program?

Jerry: Yes, a two-year program, year round.

Eric: How many students are in the previous class? Did graduation just occur in December, is that how it works?

Jerry: Correct, the previous class was 5 students.

Eric: Tell me about your cohort.

Jerry: It’s a very interesting group with a diverse range of backgrounds and interests. The ages range from 19 to my age, 62. Two women, six guys, five of them are 19-25 years old; two are in their 30s, and me. One of the young women is from South Korea and came to the US specifically to go to watchmaking school in Oklahoma.

Eric: For what reason?

Jerry: Her parents own a jewelry store in Korea and they suggested watchmaking school and thought that coming to the US would be a good opportunity. I have great admiration for people who can move to a foreign country with a vastly different culture and language and start a career. I give her a lot of credit for that.

—

My classmates have a range of backgrounds from jewelry to the military to IT. One student just graduated from high school in 2016.

—

Eric: That’s amazing. Tell me about the other lady in your class.

Jerry: She’s from Virginia and she became interested in watches through music boxes. She became interested in music boxes with her father’s influence and spent a lot of time going to flea markets and antique stores and buying music boxes and taking them apart and then fixing them.

Eric: That’s amazing. Does she plan to work with watches and sort of continue with music boxes as a hobby? Or really focus on music boxes after she graduates?

Jerry: No, she plans to work as a watchmaker. She worked at a jewelry store in Virginia and has some hands on experience with watches, so she had some familiarity by the time she came to Oklahoma. She is without a doubt the sweetest person I’ve ever met in my life. I’m so happy for her, since she has a short internship at a NC jewelry store during our summer break.

Jerry: My classmates have a range of backgrounds from jewelry to the military to IT. One student just graduated from high school in 2016.

Eric: That’s great, alright perfect. Tell me about your program. What was your first year like, starting from day one?

Jerry: The first year program had two main elements to it: Micromechanics and Theory. One instructor teaches the first year for both Theory and Micromechanics. Our instructor, Ahmed Asif Ashraf was from Bangladesh and he was a very good instructor.

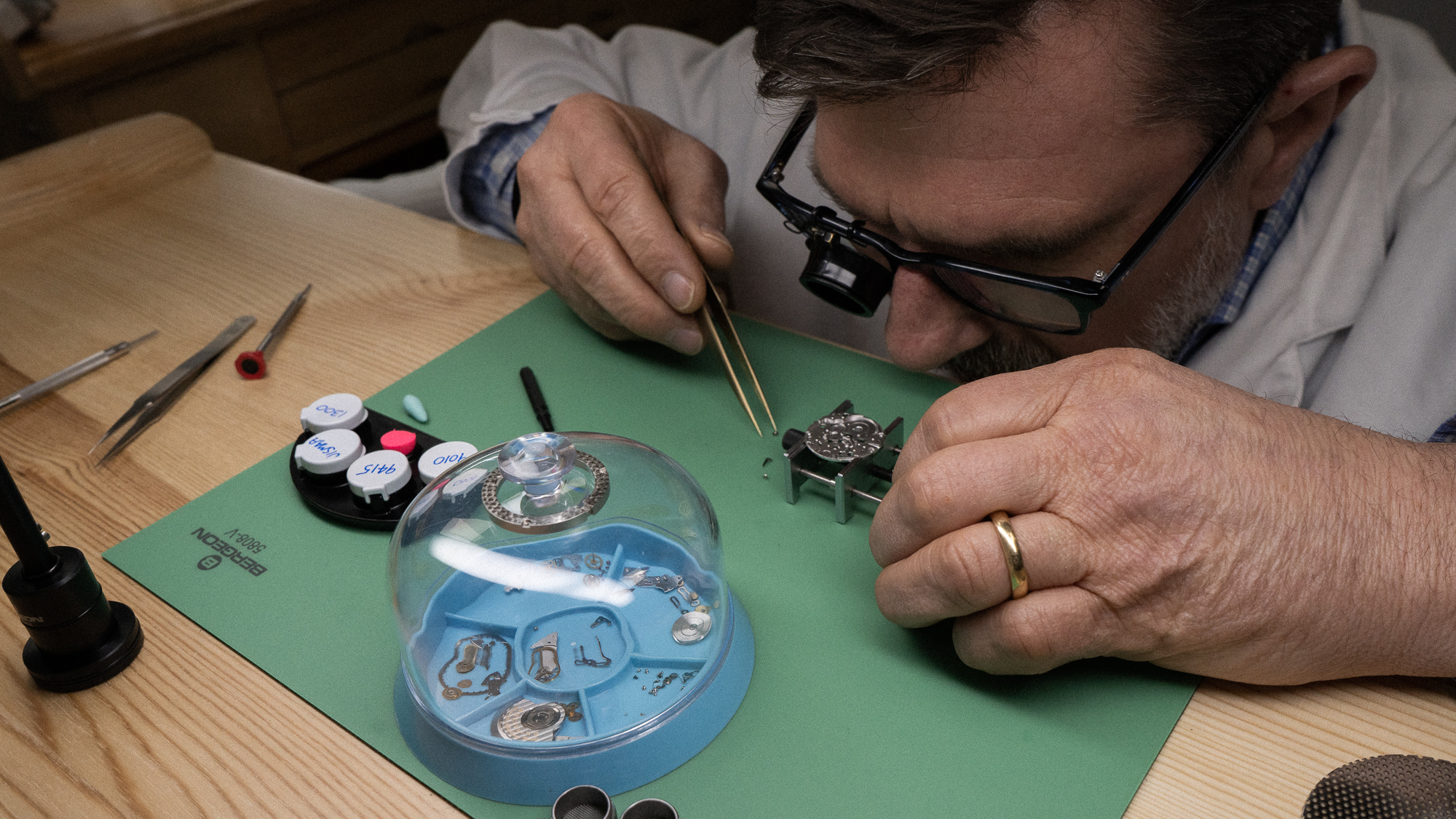

Each week we spent 2-3 days in the Micromechanics classroom wearing blue lab coats, learning basic machining, forming, heat treating and joining techniques as they apply to watchmaking, primarily by tools. The other half of the week was spent in the Theory classroom wearing white lab coats learning horological history, watch mechanisms and watch service techniques. It’s a tremendously comprehensive curriculum, which I loved.

Eric: Tell me how the year is broken down in terms of time. Is it a quarter system?

Jerry: The program is full time, year round, with three semesters per year. Unlike Lititz, NAIOSW and the Nicolas G. Hayek Watchmaking School in Miami, which are all tuition-free, OSUIT and North Seattle College are both degree-granting programs leading to an Associate of Applied Science Degree in Watchmaking and Microtechnology. As a result, there are math, physics and general education requirements to earn the degree. In my case, I had those requirements covered by virtue of my BS in Mechanical Engineering degree.

Each semester is broken into two eight-week courses. First semester courses were Basic Microtechnology and Advanced Microtechnology I. This included horological history, basic time-only watch theory, disassembly, cleaning, assembly and lubrication, with first semester micromechanics focused on technical drawing, measuring, sawing, drilling, filing, filing, and more filing (laughs). OMG. A LOT of time is spent learning precision filing! A major test of skill, endurance, patience and commitment!

Second semester courses were Advanced Microtechnology II and External Watch. These courses involved more precise lathe turning operations and more sophisticated tools and parts. External Watch covered cases, gaskets, bracelets, bezels, crowns, crystals, pushers, disassembly, reassembly, cleaning, buffing and polishing.

To finish the first year, the third semester courses were Quartz Watch Repair and Mechanical Watch Repair. The Theory portion of the semester involved quartz and mechanical watch service, including calendar functions. Third semester Micromechanics was primarily focused on making our individual school watches.

Eric: Oh you did, already, a school watch?

Jerry: Yes. Essentially what we did is we manufactured our own bridges (barrel bridge, gear train bridge and balance bridge) for an ETA 6497-1 movement. Most of us also purchased our own cases, dials, hands and bracelets or straps to complete the watch.

Eric: Can you provide a photo of the school watch? That would be great and the movement would be good, too.

Jerry: Yes I can do that.

Eric: So what’s ahead for this school year starting in January?

Jerry: For second year we will be in a third classroom, but only one classroom for the entire year. We cover escapements, oscillators, automatic mechanisms and chronographs. The second year courses are Escapement/Oscillator, Precision Timing/Automatic Watches, Chronograph Watches, Shop Management/Workflow Studies, Estimating/Quality Control and Advanced Watch Repair. The second year is very challenging due to the need for much of the work to be done under higher magnification (8x to 10x) and due to the sensitivity of the adjustments. We also delve much deeper into the theory and troubleshooting.

Eric: That’s great. Have they touched upon vintage watches really, or do you think they will?

Jerry: We definitely discuss the special challenges of construction differences, parts availability, materials and lubricants for vintage watches. We also learn fundamental techniques like building a hairspring from scratch and vibrating a hairspring, although most of us are unlikely to do this in the field. We’re learning watch service procedures that will apply to most any watch we’re tasked with servicing, but we’ve been cautioned to recognize that, as beginning watchmakers, we’re not yet sufficiently experienced to be watch restorers, since that implies the need for much greater micromechanics and part manufacturing expertise.

A student’s success in the OSUIT program is determined in a couple of different ways. Everyone who successfully completes the program requirements will graduate with the AAS degree in Watchmaking and Microtechnology. In addition, we can earn SAWTA certification if we successfully pass the SAWTA certification examinations (which I’ll discuss shortly). Lastly, we are also eligible for the American Watchmakers and Clockmakers Institute (AWCI) CW21 certification if we successfully pass AWCI’s examinations. The SAWTA and CW21 certifications are not required to graduate from the OSUIT program with the AAS degree.

Since Rolex supports the OSUIT program, our certification testing is under the SAWTA guidelines.

SAWTA is the Swiss American Watchmakers Training Alliance, which was created a few years ago by Rolex. As stated on the SAWTA.org website, “SAWTA was founded to ensure a standardized curriculum design, implementation, proficiency testing and certification primarily for the Rolex-funded watchmaking schools in the United States.”

“The principal outcomes of our SAWTA curriculum are graduates who are qualified for employment in environments that are typically perceived as challenging, since they require a wide range of hard/soft skills and knowledge, like technical positions in high-end retail environments or advanced technical positions in service centers of the watch industry. In two years, our students begin to learn the profession in its full scope, both in theory and in practice.”

“The SAWTA curriculum is unique as it covers high-end watch service in its entire spectrum: repairing movements, refinishing cases and bracelets, casing the movement, waterproofing the watch – as well as necessary administrative skills (order/inventory of spare parts, bookkeeping), general professionalism when it comes to communication with customers and suppliers, and knowledge of the industry – all skills needed by an independent watchmaker.”

Prior to SAWTA, US watchmakers could be AWCI certified or WOSTEP certified (Watchmakers of Switzerland Training and Education Program) or both. SAWTA was created with a greater emphasis on case and bracelet finishing than the WOSTEP curriculum offered at the time. Currently in the US, watchmakers can be certified to SAWTA, WOSTEP and/or AWCI standards.

Eric: Oh that’s interesting. Tell me about your examinations, sort of how you’ve been graded for this first year.

Jerry: For the two-year program there are a total of four SAWTA certification exams: Two in the first year and two in the second year. All four certification exams must be passed to earn SAWTA certification. Each exam consists of a 1-2 hour written test and an all-day practical test. The written portion covers watch theory and possibly micromechanics principles.

For the first practical exam, we were required to make a winding stem from scratch. For the second practical exam, we were required to service a quartz watch complete including disassembly, uncasing, cleaning, reassembly, lubrication, encasing, functional testing and water resistance testing.

Eric: Was there a specific type of quartz watch you used?

Jerry: It was an ETA 955.112 quartz movement with a generic dial, hands and case.

The important thing about the certification exams is that if you fail the written and/or practical portion, you get one re-take opportunity for the failed portion, usually 1-2 months later. If you don’t pass the retake you will not earn SAWTA certification. You can certainly continue with the program because anyone who successfully completes the OSUIT program will still earn the Associate of Arts Degree in Watchmaking and Microtechnology. I believe the same applies to North Seattle College program, since they are the two degree-granting watchmaking programs.

Eric: Do your classmates, like the student who just graduated from high school; does he have to take other courses then?

Jerry: Yes he did, as well as some of the other students who didn’t have transferable credits from another institution. So some classmates were taking government, or physics or math classes last year to meet those requirements, along with 6.5 hours of watchmaking class Monday through Friday. Everyone has now met all the non-watchmaking requirements, so we’re all attending watchmaking class only this year.

Eric: Did they take that in addition to the other course during this program?

Jerry: Yes.

Eric: So they were quite busy then?

Jerry: Yes! Watchmaking is 7:30 am to 3:30 pm each day, Monday through Friday. We have a 90-minute lunch break daily, so some classmates had to take these other required courses during the lunch break.

Eric: Ok, and then have you passed all your exams?

Jerry: Yes.

Eric: That’s good.

Jerry: Yes.

Eric: And what’s your ambition after you finish the program next December?

Jerry: Since my home is here in the NYC area, my goal is to work as a watchmaker in a service center, major brand boutique in Manhattan, or a jewelry store.

Eric: And ideally in New York?

Jerry: Ideally in the New York area, yes. I’ve been here 17 years now and I’m established here. Since NYC is the center of US watch retailing, there are many major-brand boutiques and retailers in Manhattan, as well as several service centers in the area. I am currently speaking with retailers, independent watchmakers and service centers to learn as much as possible about the different watchmaking environments to find the best fit for me.

In addition to my watchmaking education, my aerospace program management and technical marketing experience, along with some retail experience give me a range of skills that may benefit certain employers.

Eric: Right, that’s great, and we’ve covered a lot. We’re 40 minutes in. I thought it would be interesting for you to describe a little about your tour through Germany and Switzerland last summer.

Jerry: Oh yes, yes.

Eric: Tell me a little about that with your stepson Will.

Jerry: My wife surprised me for my birthday in 2016 with a trip to Switzerland and Germany with my stepson before he started college in the fall. He is also a big watch fan, so I refer to it as our “watch pilgrimage.” The two of us had a four-week road trip from Zurich to Geneva and then to Glashütte, with the primary goal of seeing and doing everything we could that was associated with watches.

Eric: Just the two of you?

Jerry: Just the two of us. We had a rental car and stayed in hostels to keep our expenses down, but we visited every dealer, retailer, museum and manufacturer that we could. And of course, you know, with your help, we were privileged to tour F.P. Journe’s manufacture and meet Monsieur Journe, which was incredible.

Eric: You said that one of your classmates was a big F.P. Journe fan and lost his mind when you said you met him? (chuckles)

Jerry: Oh yes, Drew Wolf, one of the second year students who graduated in December 2017.

Eric: That’s awesome. And for the students that just graduated this year, the five students, do you know where they’re going?

Jerry: Oh yes, that’s a good point. Amir Shaikh, who is from India with many watchmakers in his family, is TBD. His father is a watchmaker at the Richemont service center in Dallas. John Ogilsby is at an Official Rolex Jeweler (ORJ) in Memphis. Dustin Schramm had a kidney transplant shortly after graduating. Haden Hicks is at a watch retailer in Highlands Ranch, CO. Drew Wolf, the F.P. Journe fan, got a great opportunity at an ORJ in Cleveland. Drew was a very supportive classmate to everyone in the program and he really emphasized the family aspect of our program. My classmates and I are very grateful to all of the previous class for their mentoring and interest in our development. They welcomed us with open arms and helped us in many ways, so we are fortunate.

Eric: (chuckles) That’s great.

Jerry: Ours is the largest class that OSUIT has had in several years.

Eric: That’s interesting. Do they attribute it to anything? Just watch knowledge and people getting interested in watches?

Jerry: Yes. I think it’s partially a coincidence and partially due to increased awareness of watchmaking that has come about with more watch-related websites each year. Our classmate Jonathan Colburn happens to be a veteran and literally just learned about watchmaking a few weeks before our class started.

Eric: And they were that fast to respond to his application?

Jerry: Yes, he lives in Oklahoma. It’s so unfortunate that his health issues forced him to leave the class, because he is very, very skilled, and he’s very fast. Imperturbable!

Eric: So he applied two weeks before the program and they accepted him?

Jerry: Yes. OSUIT was started right after World War II with a primary goal of helping veterans learn trades and they have continued to support veterans very strongly, so they have the processes and people in place for veterans to come into the school easily, regardless of the specific program.

Eric: That’s great.

Jerry: Yes, very nice.

Eric: What were some of the other highlights you saw in Switzerland and Germany? Did you see the Beyer Museum in Zurich?

Jerry: Yes, we went to the Beyer Museum, which was fantastic. We also went to the Breguet Museum at the Breguet Boutique, but it was closed for renovations.

Eric: Did you tour the Patek Philippe Museum?

Jerry: Yes we went to the Patek Museum. It’s so comprehensive and really opened my eyes to aspects of watchmaking that I was not aware of, like mourning watches that were worn to mourn departed loved ones. They often have black enamel decoration and sometimes had fobs of braided hair from the deceased person. We also were able to get into one brand’s museum in an interesting way.

Eric: It was the security guard in the parking lot or something funny?

Jerry: Yes (chuckles). We hadn’t received confirmation to visit the museum, but we found it one afternoon and were snooping around the parking lot when the security guard came to check on us. We explained the situation and he let us in to speak with the receptionist. So we explained our situation to her and she said she would forward our request. The next morning at breakfast I got an email stating that if we could be there in 40 minutes, we would be given a tour. And I jokingly told my stepson “Oh my goodness, it’s like a drug deal. Stop eating, put everything down, run out the door go, go, go!” (laughter) We got there in time and had a wonderful tour of the museum.

Eric: (chuckles) That’s awesome.

Jerry: We eventually worked our way down through Switzerland to the Vallée de Joux.

Eric: Did you see Jaeger-LeCoultre by any chance, or no?

Jerry: No, but in the Vallée de Joux, we visited the Espace Horloger, which is a very interesting museum with great exhibits of watches and Vallée de Joux history, including a very nice film. Since I had applied to watchmaking school, I really appreciated the detailed information about careers in the watch industry. It included much more than watchmaking: gem setting, engraving, design, development, manufacturing, micromechanics and all these different occupations that one might choose to pursue in that region. It described the education requirements, available schools, specific job titles and details of the work. It was very eye opening regarding the industry as a whole, rather than just watchmaking as a service position as we primarily know it in the US.

Eric: That’s fantastic.

Jerry: In Glashütte, Germany, we toured Glashütte Original and Mühle Glashütte. Mühle Glashütte was a great experience because it was by far the smallest manufacture we visited and is family owned, so it was a great contrast to other places we visited, because it was a very personal tour. Given my background, I appreciate their experience as instrument makers as well as watchmakers. I also really appreciated their generosity in accommodating us.

Eric: Thank you, again, Jerry for your friendship and pursuing your passion. You were one of the influences that led me to pursue my own dream and start Wind Vintage, and I hope to send you some watches to service soon!

Jerry: My pleasure and thank you for all of your support as I pursued this dream!

March 2020 Addendum:

Eric: Jerry, what are you doing now?

Jerry: I am a watchmaker at Swiss Precision Watchmaking and Repair in the Financial District of New York City. The company plans to add a second facility in midtown Manhattan. We are an authorized service center for several brands, with multiple certified watchmakers, servicing manual wind, automatics, quartz, and vintage watches. Chronographs, split second chronographs, moon phase, perpetual calendars, power reserve and more are our specialties. I have been thrilled to continue developing my skills as a watchmaker and continue working on more complicated pieces. Vintage pieces, such as chronographs, are some of my favorite watches to service.