How Rolex Became Rolex: The Automatic “Perpetual” Movement (Part 2)

A Perpetual Quest

Following the development of the Oyster case, which I covered within my article ‘How Rolex Became Rolex: The Oyster Case Story (Part 1)’, the automatic movement marks the second monumental innovation in a triad that propelled Rolex to become the preeminent watchmaker and potentially the most recognizable brand in the world.

Rolex currently markets itself as being on a perpetual quest for accuracy and making the world a better place through its charitable endeavors. However, the Perpetual started years prior under Hans Wilsdorf. As with the Oyster, simply creating the right product wasn’t enough to propel a watch company to greatness. Wilsdorf’s vision, genius, and perhaps a little luck led to Rolex’s unrivaled success.

Challenges For The Oyster

After releasing the Oyster case in 1926, and the subsequent success following the 1927 English Channel attempt by Mercedes Gleitze, the Rolex Oyster’s reputation began to develop as an industry leader. The early Oyster cases, however, did have some flaws, particularly the degradation of water resistance with time.

Automatic wristwatch movements were not the standard during the conception of the Oyster, so users were accustomed to manually winding their watches. Wilsdorf had the vision to create ‘an automatic watch with a movement that would autonomously and continually wind itself to assure uninterrupted and regular running’.

Many early Oyster cases were made from soft metals, such as gold or silver, with the crown tube being manufactured from the same material. This daily interaction of unscrewing and screwing of the crown to power the watch led to the crown tube becoming worn, ultimately compromising the water resistance of these early Oyster watches.

The quick fix from Rolex was to implement a threaded steel tube to replace the original soft metal tube. As a result, many early Oysters have undergone restoration with replaced tubes for longer utility.

Hans Wilsdorf. Image credit: Interview 1959

Continued Innovation

As has become expected of watch manufacturers today, incremental upgrades to existing products are important and provide consumer confidence that watches are made with the best technology available. It is pretty well recognized that no other manufacturer has demonstrated this effort more than Rolex. In the late 1920s, Wilsdorf was not resting on his laurels and worked with suppliers to improve his products.

A clear example of this endeavour was the development of a tool for tightening case backs and bezels. This improved water resistance and provided a tool to serve those seeking to push the limits of human achievement. A case back tightening tool was patented by Wilsdorf in 1929 (GB353722A) and this reflected his continual effort to make better products.

https://worldwide.espacenet.com/patent/search/family/004510260/publication/GB353722A?q=GB353722A

Previous automatic watches

The concept of an automatic watch was well known at the time of the Oyster. In the 1770s Abraham-Louis Perrelet developed a system for transferring the energy from the movement of the user to the mainspring thus powering it.

Following this development by Perrelet, a series of innovations took place in rapid succession surrounding the automatic winding watches. The history here is complex and a comprehensive study has been conducted by Richard Watkins in his book ‘The Origin of Self-Winding Watches 1773-1779’. Self-winding pocket watches never really took off, but the technology returned in the early 20th century with the rise in popularity of wristwatches.

It is a common misconception that Rolex invented the first automatic winding wristwatch. During the 1920s on the Isle of Man, John Harwood developed an automatically winding movement for wristwatches. It is said that he noticed children playing on a seesaw, and this inspired him to power his watch movement in a similar way. Similarly, Leon Leroy and Leon Hatot were also working on this technology around the same time.

Following the successes of the Oyster, Rolex worked closely with movement manufacturer Aegler. Wilsdorf tasked Aegler in 1931 to ‘invent an automatic winding mechanism that turns back and forth silently, smoothly and without buffer’. The technical director of Aegler, Emile Boner rose to the challenge.

The first self-winding Rolex movement cal 620. Image credit: Rolex

The resulting movement used a semicircular rotor for unidirectional winding, built on the difficulties faced in previous automatic movements. Namely, it used a modular system with the automatic winding works situated on a bridge that could be removed for servicing. It also featured the ability for the movement to be hand-wound independently from the automatic works.

Boner also included a clutch-type mechanism on the mainspring ensuring that the spring could never be overwound, nor run out of tension. The reduction in tension towards the end of a spring unwinding had previously been a challenge as it led to ‘knocking’ and a reduction in accuracy impacting an attempt at chronometer certification. In short Boner’s movement solved a number of challenges facing wristwatches of the time.

None of this innovative work went unprotected. Two patents were granted in 1933 following the debut of the Oyster Perpetual in 1932 which used the Caliber 620. CH160803A and CH157995A protected the winding of a wristwatch by an oscillating mass and the transmission of energy to a mainspring from two different sources. A third patent, CH170938A, later protected a specific type of bi-directional winding transmission in 1934.

CH160803A protected a watch movement with an oscillating weight attached. In the cross-section through a watch in figure 1, this weight is marked as 12 and rotates about screw 11.

CH157995A relates to a ratcheting system that allows the watch to be wound from two different energy sources, both simultaneously and separately. A particularly interesting point to note is the mention of winding using the crown but no specifics as to another energy source. Maintaining a certain level of vagueness was important, not to keep the invention of an oscillating weight under wraps, but more to allow for broad interpretation in case another source of energy could be used in the same system.

Finally, CH170938A discloses the use of an automatic transmission works for transferring the kinetic energy of oscillating weight, 1, to the mainspring when the weight rotates in either direction. It is important to note that this protects a system on one axis, unlike the two adjacent wheel systems we’re used to today.

These patents were successful, evidenced by the lack of other large-scale movement manufacturers who produced automatic movements after their filing. The only notable exception was the Caliber 692 released in 1942 by Felsa. The key difference offered by Caliber 692 was the ability for bi-directional winding, something that Rolex had yet to utilise in their movements by that date. Felsa could do this by using a system that did not infringe on the Rolex patent for transferring energy from both directions of rotation of the oscillating weight to the mainspring.

Early Perpetual or “Bubblebacks”

The rollout of Rolex’s perpetual movements was fast and involved modification of current movements that allowed them to be self winding. This is a testament to the work of Aegler who invented the modular system making it easier to adapt current movement manufacturing to the up-to-date perpetual version.

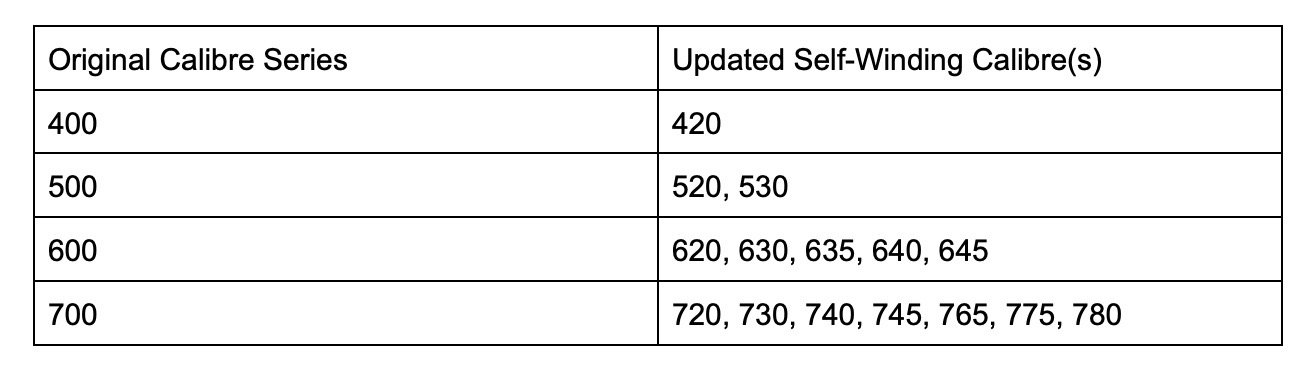

The Rolex calibre 600 served as the original base for applying the self-winding module. This can be seen in the developments of calibres 620, 630, 635, 640 and 645. Below is a table of the original manual-wind movement series and the resulting movements that were developed until 1950.

Each of these series followed a set movement diameter, hence the updates across the board. Multiple calibers in the same series indicates varying complications along with updates to shock absorption etc.

The important change in 1950 was the introduction of the cal 1030, a dedicated self-winding movement. It was the first Rolex in-house designed chronometer calibre featuring in many Oyster Perpetuals, Explorers and Submariners from 1950 onwards. It can also be noted that in the cal 1030, the famous red-anodized aluminium wheels in the self-winding module are featured for the first time. These red aluminium wheels allowed bi-directional winding, the first time it featured in a Rolex calibre.

The first Rolex Oyster Perpetual, 1931. Image credit: Rolex

The new Oyster Perpetual watches in 1931 featured the aforementioned pre-1000 calibre movements. In 1933 the Oyster Perpetual was updated to what is commonly referred to as the Bubblebacks.

While Rolex never officially used this name for the Oyster Perpetuals, the word is used to describe Oyster Perpetual watches between 1933 and 1955 with a protruding rounded caseback. This aligns with the addition of the self-winding modules to movements and the additional ‘bubble’ to the casebacks of Oyster Perpetual watches was due to the increased movement thickness.

A wide variety of so-called Bubblebacks were produced across numerous reference numbers, but in line with the introduction of the 1000+ series of calibres, they were phased out in the 1950s with the introduction of Oyster Perpetuals that more closely resemble those in the present Rolex catalogue.

What the perpetual allowed

Without the development of a better self-winding mechanism for wristwatches, many complications taken for granted today would struggle to exist such as date, day, month and moonphase displays. Take the date display, for example. In order to correctly display the date on every day of the month the watch must be wound every day. By removing the wear involved and resistance to winding a watch and adding a self-winding mechanism, the date will be correct every day the user picks up the watch from their nightstand as long as they wore the watch the day before.

This was exactly what Rolex did with the cal 740 in 1945, Rolex released the Datejust, a watch that displayed the date through a dial window. It’s certainly a watch that has become synonymous with Rolex and the luxury timepiece. Furthermore, it helped propell Rolex to its status as the preeminent watchmaker.

Ref: 6062. Image credit: Phillips.

The same reasoning for a date window being of greater convenience on an automatic wristwatch applies to increased complications such as day displays, higher calendar complications and moonphases. For example, it allowed iconic references such as Rolex "Padellone" reference 8171 to exist (complete calendar, moonphase) as there would have been great inconvenience with readjusting the calendar works winding was forgotten after a day or two.

This is at least a factor in why Rolex has seen the success it has. More simply Rolex was the first watch manufacturer with a ‘waterproof’ and self-winding wristwatch in the Oyster Perpetual. The combination propelled Rolex to become a household name and a name synonymous with high quality. Part of this is due to further development and never resting on their laurels, continually seeking to improve customer experience and the watches that they offer, the rest is marketing genius with the likes of Gleitze’s vindication swim and aspiring newspaper ads.

Endnote: Many of the patents mentioned were filed for in multiple jurisdictions. For clarity, CH160803A is DE586719C in Germany, FR747467A in France, and US1981297A in the United States. CH157995A is DE592986C in Germany. The other patents referenced in this article are published only with the patent numbers as displayed.